Crosslinked polyethylene insulated power cable for coal minesFirst, product standardsThis product is produced according to MT818-2009 "Flame retardant Cable for Coal mine" and related enterprise standards.2. Scope of applicationThis product is suitable for fixed laying in power distribut

Crosslinked polyethylene insulated power cable for coal mines

First, product standards

This product is produced according to MT818-2009 "Flame retardant Cable for Coal mine" and related enterprise standards.

2. Scope of application

This product is suitable for fixed laying in power distribution network or industrial equipment with rated power frequency voltage of 10 kV and below.

3. Working temperature and laying conditions

a) The maximum allowable long-term temperature of the cable conductor shall not exceed 90℃.

b) The maximum temperature of the cable conductor shall not exceed 250℃ during short circuit (the maximum time shall not exceed 5S).

* Ground laying

d) The ambient temperature during cable laying shall not be lower than 0℃.

e) Cable bending radius:

Single-core cable :20(D+d)±5%

Three core cable :15(D+d)±5%

Fourth, cable model

Model name Applicable scope

MYJV coal mine copper core crosslinked polyethylene insulated polyvinyl chloride sheathed power cable

Indoor tunnels and cable trenches and other places can not withstand mechanical external forces.

MYJV22 Copper core crosslinked polyethylene insulated steel tape armoured PVC sheathed power cable for coal mine

MYJV32 coal mine copper core crosslinked polyethylene insulated fine wire armoured PVC sheathed power cable

MYJV42 copper core crosslinked polyethylene insulated thick steel wire armoured polyvinyl chloride sheathed power cable for coal mine

Indoor, tunnel, cable trench or directly buried underground, can be used in wet environment and high groundwater level, can withstand a certain mechanical external force and a certain tension.

5. Production scope

Number of cores Rated voltage (kV)

0.6/1 1.8/3 3.6/6 6/10, 8.7/10

Nominal section

MYJV 3 1.5-300 10-300 25-300 25-300

MYJV22 3 4-300 10-300 25-300 25-300

MYJV32 3 4-300 10-300 25-300 25-300

MYJV42 3 4-300 10-300 25-300 25-300

6. Voltage test

1. The voltage test should be carried out at the ambient temperature, and the manufacturer can choose to use power frequency AC voltage or DC voltage.

2. Test voltage

The 0.6/1 kV power frequency test voltage is 2.5U0+2kV, and the single-phase test voltage corresponding to the standard rated voltage is as follows:

Rated voltage U0kV 0.6 1.8

Test voltage kV 3.5 6.5

Time min 5 5

(1) If a three-phase transformer is used to perform a voltage test on a three-core cable at the same time, the phase-to-phase test voltage should be 1.73 times of the data listed in the above table.

(2) When the voltage test uses DC voltage, the DC voltage value should be 2.4 times the power frequency AC voltage value.

(3) In any case, the voltage should be gradually increased to the specified value.

(4) Voltage test, partial discharge test

1, the test voltage should be carried out on the disk cable. When the voltage is 1.5U0, the discharge capacity of the PVC insulated cable should not be greater than 40pC. The discharge capacity of the XLPE insulated cable with rated voltage U0 of 8.7kV and below is not more than 20 pC.

2. Test voltage

The power frequency test voltage of 3.6/6kV and above is 2.5U0, and the single-phase test voltage corresponding to the standard rated voltage is as follows:

Rated voltage U0kV 3.6/6 6/6, 6/10 8.7/10

Test voltage kV 11 15 22

Time min 5 5 5

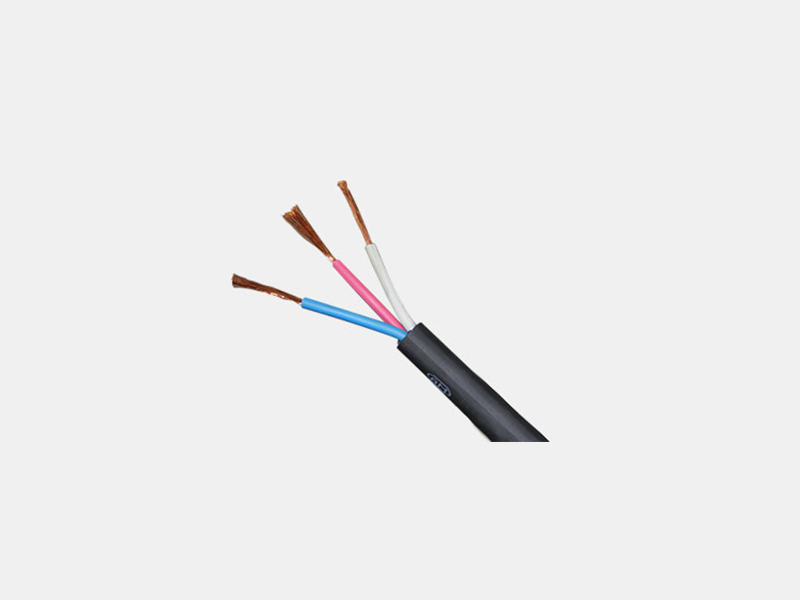

PVC insulated flame retardant power cable for coal mine

First, product standards

This product is produced according to MT 818-2009 "Coal mine resistance Cable" and related enterprise standards.

2. Scope of application

This product is suitable for fixed laying in power distribution networks or industrial installations with rated power frequency voltage 0.6/1 kV and below.

Third, the use of characteristics

Rated power frequency voltage: U0/U 0.6/1kV.

The maximum allowable long-term temperature of the cable conductor shall not exceed 70℃.

The ambient temperature should not be lower than 0 ° C when the cable is laid.

Cable bending radius: not less than 10 times the cable diameter.

Fourth, cable model

Model name Applicable scope

MVV coal mine copper core PVC insulation PVC sheathed power cable indoor tunnels and cable trenches and other places, can not withstand mechanical external forces.

MVV22 coal mine copper core PVC insulated steel tape armouring PVC sheathed power cable indoor, tunnel, cable trench or directly buried underground, can be used in humid environment and high water table place, can withstand a certain mechanical external force and a certain tension. Indoor, tunnel, cable trench, shaft or directly buried underground, etc., can withstand mechanical external forces and a certain tension.

MVV32 coal mine copper core PVC insulated fine wire armouring PVC sheathed power cable

MVV42 coal mine copper core PVC insulated thick steel wire armored PVC sheathed power cable

5. Voltage test

1. The voltage test should be carried out at the ambient temperature, and the manufacturer can choose to use power frequency AC voltage or DC voltage.

2. Test voltage

The power frequency test voltage is 2.5U0+2kV, and the single-phase test voltage corresponding to the standard rated voltage is as follows:

Rated voltage U0 (kV) 0.6 1.8

Test voltage kV 3.5 6.5

Time min 5 5

(1) If a three-phase transformer is used to perform a voltage test on a three-core cable at the same time, the phase-to-phase test voltage should be 1.73 times of the data listed in the above table.

(2) When the voltage test uses DC voltage, the DC voltage value should be 2.4 times the power frequency AC voltage value.

(3) In any case, the voltage should be gradually increased to the specified value.

3. Lay and install

Direct buried laying

(1) When the single-core cable does not touch the laying, the cable center distance is 2 times the cable diameter.

(2) Soil temperature: 25℃

(3) Long-term maximum operating temperature of conductor: 70℃

(4) Soil thermal resistance coefficient: 1.0℃M/W

(5) Direct burial depth: 0.7m

Current carrying capacity correction coefficient under different soil temperatures:

Soil temperature 20℃ 25℃ 30℃ 35℃ 40℃

Correction factor 1.04 1 0.96 0.92 0.87

Laying in the air

1. When the single-core cable is laid in parallel, the center distance is 185㎜2 and below 2 times the diameter of the cable; 240㎜2 and above for 90㎜.

2. Ambient air temperature: 40℃

3. Long-term maximum operating temperature of conductor: 70℃

Current-carrying correction coefficient at different ambient temperatures:

Ambient air temperature 20℃ 25℃ 30℃ 35℃ 40℃ 45℃

Correction factor 1.2 1.22 1.15 1.08 1 0.91

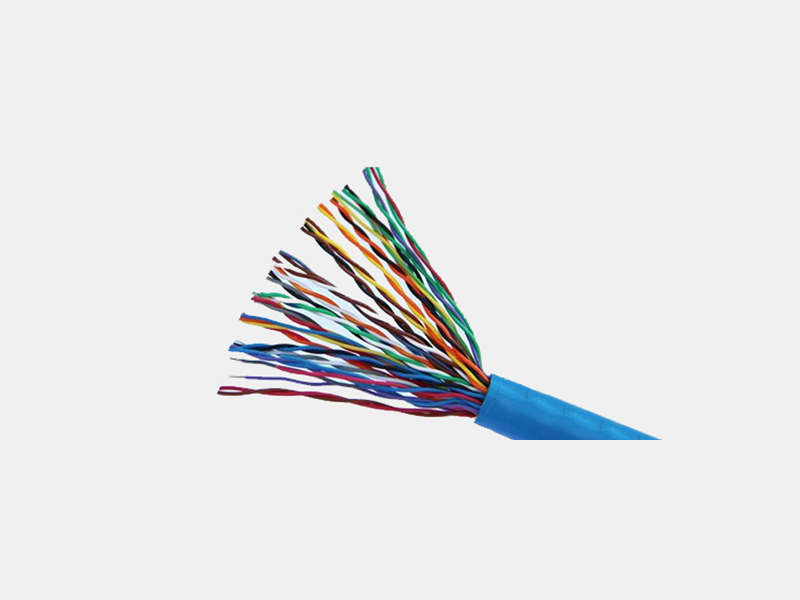

35kV and below crosslinked polyethylene insulated power cables

I. Implementation of standards

This product implements GB/T 12706-2008 and enterprise standards

Flame retardant properties in line with GB/T 18380-2008, GB/T 19666-2005

Second, product features and uses

This product is used in 35kV and below power transmission and distribution system, power transmission and distribution can be used. Low smoke halogen-free flame retardant, low smoke and low halogen fire resistance is higher than the normal national flame retardant standards, widely used in airports, nuclear power plants, key water conservancy projects, petroleum, chemical, transportation, high-rise buildings and other places with strict flame retardant performance requirements.

Third, the use of characteristics

Rated voltage (U0/U) : 0.6/1kV, 3.6/6kV, 6/10kV, 8.7/10kV, 8.7/15kV, 12/20kV, 18/20kV, 21/35kV, 26/35kV;

The long-term working temperature of the cable conductor shall be 90℃, and the maximum temperature of the cable conductor shall not exceed 250℃ in the case of short circuit (the longest duration shall not exceed 5 seconds);

The DC resistance of the cable conductor conforms to GB/T 3956.

The ambient temperature when the cable is laid shall not be lower than 0℃, and the minimum bending radius shall not be less than 15 times the outer diameter of the cable;

Cable laying is not limited by the drop;

Power frequency withstand voltage test:

U0 is below 3.6kV cable; 2.5U0+2kV/5min no breakdown.

U0 for 3.6kV and above cables: 3.5U0/5min no breakdown.

Partial discharge test:

When the U0 is 18KV and below, the voltage of 1.5U0 is applied, and the discharge capacity is not more than 20pc.

When the U0 is above 18KV, the voltage of 1.5U0 is applied, and the discharge capacity is not more than 10pc.

Iv. Product model and name

Model Product name

ZC-YJV copper core crosslinked polyethylene insulated PVC sheathed flame retardant power cable

ZC-YJV22 Copper core crosslinked polyethylene insulated polyvinyl chloride sheathed steel tape armoured flame retardant power cable

ZC-YJV32 Copper core crosslinked polyethylene insulated polyvinyl chloride sheathed fine wire armored flame retardant power cable

WDZC-YJY copper core crosslinked polyethylene insulated polythin hydrocarbon sheathed low smoke halogen-free flame retardant power cable

WDZC-YJV23 Copper core crosslinked polyethylene insulated polythin hydrocarbon sheathed steel tape armoury low smoke halogen-free flame retardant power cable

WDZC-YJY32 Copper core crosslinked polyethylene insulated polyvinyl hydrocarbon sheathed fine wire armored low smoke halogen-free flame retardant power cable

Note: Flame retardant grade is divided into: A, B, C three grades